Pansi pa zikhalidwe za kuuma, kuya kwakukulu kwa kudula kumagwiritsidwa ntchito roughing kuchepetsa chiwerengero cha zidutsa ndi kupititsa patsogolo zokolola za workpiece;Pomaliza, kudula kwakung'ono kumagwiritsidwa ntchito kuti mupeze mawonekedwe apamwamba.Zokhudza kulondola komaliza kwa makina opangira makina, kuwonjezera pazifukwa za chida cha makina a CNC, ziyeneranso kukhala ndi makina opangira makina, kusankha zida ndikuyika kolondola, kusankha koyenera kwa kudula, luso lokonzekera, komanso mwachangu. kuwongolera kulondola kwa dimensional.kulingalira kwathunthu.

1. Maluso okonza mapulogalamu

Kupanga mapulogalamu a NC ndiye ntchito yofunika kwambiri pamakina a NC.Ubwino ndi kuipa kwa pulogalamu yopangira ma workpiece imakhudza mwachindunji kulondola kwa makina omaliza komanso kuyendetsa bwino kwa chida cha makina.Ikhoza kuyamba kuchokera kuzinthu zingapo, monga kugwiritsa ntchito mwanzeru mapulogalamu obadwa nawo, kuchepetsa zolakwika za CNC system, komanso kugwiritsa ntchito mapulogalamu akuluakulu ndi mapulogalamu ang'onoang'ono.

1. Kugwiritsa ntchito pulogalamu yayikulu ndi pulogalamu yaying'ono

Pokonza zisankho zovuta, nthawi zambiri zimakonzedwa ngati nkhungu imodzi ndi zidutswa zingapo.Ngati pali mitundu ingapo yofanana pa nkhungu, mgwirizano wapakati pa pulogalamu yaikulu ndi yaing’ono uyenera kugwiritsidwa ntchito mosinthasintha, ndipo pulogalamu yaing’onoyo iyenera kutchulidwa mobwerezabwereza m’programu yaikulu kufikira kukonzedwako kukatsirizika.Iwo sangakhoze kuonetsetsa kugwirizana kwa miyeso processing komanso kusintha processing dzuwa.

2. Chepetsani zolakwika zochulukirapo za dongosolo la CNC

Nthawi zambiri, njira yowonjezera imagwiritsidwa ntchito pokonza chogwirira ntchito, chomwe chimatengera mfundo yapitayi.Mwanjira imeneyi, kupitilirabe kwa mapulogalamu amitundu yambiri mosalephera kumabweretsa cholakwika china.Chifukwa chake, yesetsani kugwiritsa ntchito mapulogalamu athunthu mukakonza, kuti gawo lililonse la pulogalamuyo likhazikike pachogwirira ntchito.Chiyambi ndi chizindikiro, kotero kuti cholakwika chowonjezereka cha dongosolo la CNC chikhoza kuchepetsedwa ndipo kulondola kwa makina kungatsimikizidwe.

Kulondola kwa Machining kumagwiritsidwa ntchito makamaka popanga zinthu, ndipo kulondola kwa makina ndi zolakwika zamakina ndi mawu omwe amagwiritsidwa ntchito poyesa magawo a geometric pamtunda wopangidwa ndi makina.Komabe, magawo enieni omwe amapezedwa ndi njira iliyonse yopangira makina sangakhale olondola.Kuchokera ku ntchito ya gawolo, malinga ngati kulakwitsa kwa makina kuli mkati mwa kulekerera komwe kumafunidwa ndi gawo lojambula, kumaonedwa kuti kulondola kwa makina kumatsimikiziridwa.

Kulondola kwa Machining kumatanthawuza magawo enieni a geometric (kukula, mawonekedwe ndi malo) a gawolo pambuyo pokonza.Kusiyana pakati pawo kumatchedwa Machining error.Kukula kwa cholakwika cha makina kumawonetsa kuchuluka kwa makina olondola.Kulakwitsa kwakukulu, kutsika kwa makina olondola, ndi zolakwika zazing'ono, zimakweza kulondola kwa makina.Zotsatirazi ndizofotokozera mwachidule za njira zowonjezera makina olondola a workpieces:

1. Kusintha ndondomeko dongosolo

1): Njira yodulira yoyeserera imasinthidwa ndi kudula koyeserera - kuyeza kukula - kusintha kuchuluka kwa kulumidwa kwa mpeni kwa chida - kudula ndi kudula - yesetsani kudulanso, ndi zina zotero mpaka kukula komwe mukufuna.Njirayi imakhala ndi mphamvu zochepa zopangira ndipo imagwiritsidwa ntchito makamaka popanga gulu laling'ono lachigawo chimodzi.

2): Njira yosinthira imapeza kukula kofunikira posinthiratu malo achibale a chida cha makina, kukonza, chogwirira ntchito ndi chida.Njirayi imakhala ndi zokolola zambiri ndipo imagwiritsidwa ntchito makamaka popanga zambiri.

2. Chepetsani cholakwika cha chida cha makina

--Kulondola kwa kasinthasintha kwa mayendedwe kuyenera kuwongoleredwa

①Sankhani mayendedwe olondola kwambiri

②Kugwiritsa ntchito zotengera zamphamvu kwambiri zamafuta ambiri

③Kugwiritsa ntchito mayendedwe olondola kwambiri a hydrostatic

--Sinthani kulondola kwa zida zokhala ndi ma bearings

① Sinthani kulondola kwa makina a mabowo othandizira mabokosi ndi magazini a spindle

②Sinthani kulondola kwa makina a malo okwererako ndi kubereka

③ kuyeza ndi kusintha ma radial runout osiyanasiyana magawo ofananirako kuti chibwezero cholakwacho chibwezedwe kapena kuthetseratu.

--Lowetsani moyenerera zozungulira

①Itha kuthetsa kusiyana

②Onjezani kulimba mtima

③ Homogenization ya kugubuduza chinthu cholakwika

--Kulondola kozungulira kwa spindle sikuwonetsedwa pa chogwirira ntchito

3. Chepetsani vuto lopatsirana panjira yopatsira

(1) Chiwerengero cha ziwalo zopatsirana ndizochepa, unyolo wotumizira ndi waufupi, ndipo kulondola kwapadziko lonse ndikwambiri.

(2) Kugwiritsiridwa ntchito kwa kufalikira kwa deceleration ndi mfundo yofunika kwambiri kuti iwonetsetse kuti kachilombo ka HIV kakulondola, ndipo kuyandikira kwa awiriwo kukufika kumapeto, chiwerengero chocheperako chiyenera kukhala.

(3) Kulondola kwachidutswa chomaliza chiyenera kukhala chapamwamba kuposa cha ziwalo zina zopatsirana

Chachinayi, kuchepetsa kuvala kwa zida

(1) Chidacho chiyenera kukonzedwanso chisanayambe kuvala kukula kwa chida kufika pa siteji ya kuvala mofulumira

(2) Sankhani mafuta odulira apadera kuti muzipaka bwino

(3) Zida zothandizira ziyenera kukwaniritsa zofunikira

5. Kuchepetsa nkhawa ndi mapindikidwe a dongosolo ndondomeko

(1) Kupititsa patsogolo kuuma kwa dongosolo, makamaka kuuma kwa maulalo ofooka mu dongosolo la ndondomeko

(2) Kuchepetsa katundu ndi kusintha kwake

6. Kuchepetsa matenthedwe matenthedwe dongosolo ndondomeko

(1) Kuchepetsa kutentha kwa gwero la kutentha ndikupatula gwero la kutentha

(2) Munda wa kutentha wofanana

(3) Khalani ndi chida choyenera cha makina ndi chizindikiro cha msonkhano

(4) Fulumirani kuti mukwaniritse mgwirizano wotengera kutentha

(5) Kuwongolera kutentha kozungulira

Zisanu ndi ziwiri, kuchepetsa nkhawa yotsalira

(1) Wonjezerani njira yochizira kutentha kuti muthetse nkhawa zamkati;

(2) Konzani bwino njira yaukadaulo.

Zomwe zili pamwambazi ndi njira yochepetsera zolakwika za workpiece, ndipo ndondomeko yoyenera ya ndondomekoyi ingathe kusintha bwino kulondola kwa workpiece.

Zambiri za zolemba zapamenepaZolemba zoyambira ndizofunikira kuti mumve zambiri zomasulira

Tumizani ndemanga

M'mbali mapanelo

Mbiri

Zosungidwa

Thandizani

2. Kukonzekera koyenera kwa njira zopangira

Kukhazikitsa koyenera kwa njira yosinthira ndikutsatizana ndikukonza ndi maziko ofunikira pakukhathamiritsa pulogalamu yokonza ma workpiece.Ikhoza kuganiziridwa kuchokera ku mbali ya njira yopangira makina ndi njira yodyetsera.

Pochita CNC mphero ya workpiece, m'pofunika kusankha njira yoyenera chakudya malinga ndi zofunikira zaumisiri workpiece kuonetsetsa kudula molondola ndi processing dzuwa la workpiece.Pamene mphero yakunja kwa ndege yogwirira ntchito, njira zodulira ndi kudula za chida ziyenera kukonzedwa.Yesetsani kudula ndi kutuluka motsatira mzere wowongoka wa kokhota kuti mupewe zizindikiro za mpeni pa mphambanoyo.Panthawi imodzimodziyo, mu mphero, mphero pansi kapena mmwamba mphero ziyenera kusankhidwa malinga ndi momwe ntchitoyo ilili.

3. Kusankha chida ndikuyika kolondola

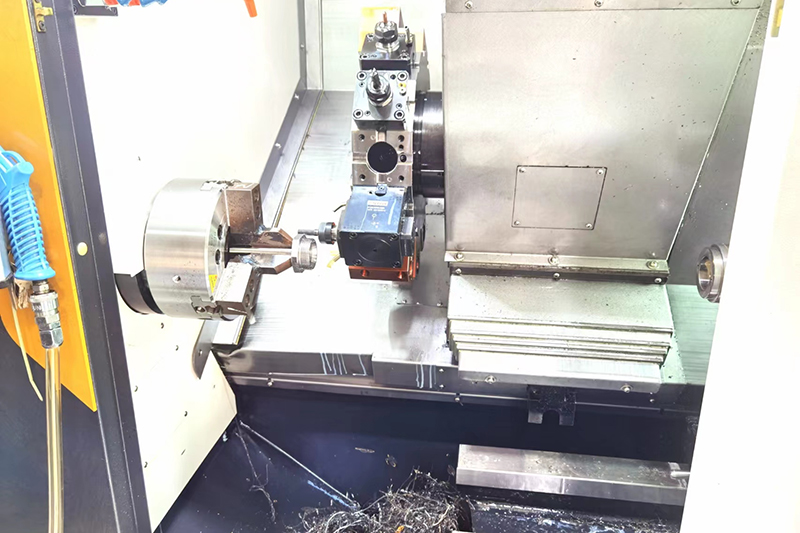

Kaya ndi CNC Machining kapena Machining wamba, chida mwachindunji amachita pa workpiece, kotero kusankha ndi unsembe wake ndi zinthu zofunika kwambiri Machining kulondola ndi pamwamba khalidwe la workpiece.Makamaka pamene workpiece ndi kukonzedwa pa CNC Machining pakati, zida amasungidwa mu magazini chida pasadakhale, ndipo pamene processing akuyamba, iwo sangakhoze m'malo mwa kufuna.Choncho, mfundo yaikulu ya kusankha chida ndi: kuyika kosavuta ndi kusintha, kukhazikika bwino, kukhazikika kwakukulu komanso kulondola kwambiri.

4. Kusankha koyenera kwa kudula ndalama

Kutsimikiza kwa kuchuluka kwa kudula ndi gawo lofunikira pakupanga makina a CNC.Kukula kwake ndi gawo lofunikira la kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake.Kusankhidwa kwa kuchuluka kwa kudula kumaphatikizapo kuthamanga, kudula kumbuyo ndi kuchuluka kwa chakudya.Mfundo yofunikira yosankhidwa ndi: pamene kukhwima kumalola, kudula kwakukulu kumagwiritsidwa ntchito popanga roughing kuchepetsa chiwerengero cha madutsa ndi kupititsa patsogolo zokolola za workpiece;kuzama kocheperako kumagwiritsidwa ntchito pomaliza kuti apeze mawonekedwe apamwamba.

Nthawi yotumiza: Sep-26-2022